Wisconsin Parts Database Instructions and Discussion Team/Group > WISCONSIN

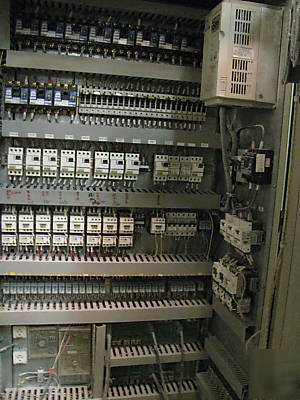

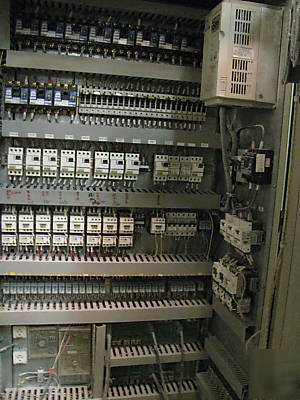

> Electrical Components

> Add

> Used

> Without Warranty

> Extruder 72MM twin screw 42:1 co-rotational 2003 (2)

Extruder 72MM twin screw 42:1 co-rotational 2003 (2)

Extruder 72mm (3") Twin Screw Co-Rotational 2003 L:D 42:1

2 (two) - Compounding Lines Mfg. Sino-Alloy machines Model# PSM72, Side feeder, Screen Changer, 150 hp drive, 300 RPM, double vented , K-Tron Loss-in-weight, transfer systems. Both 72mm design is setup the same, upto the screen changer... Then:

A.) One extruder setup for Cold cut, 17 hole die, waterbath, strand dryer, 14" Pelletizer, screener.

B.) Second extruder is Hot cut, 36 hole round die, 6 knife hot face cutter, pumper to spin dryer and onto screener.

Main resin processed PP into unfilled colors, Glass and Talc filled, Screws look good low wear.

(Sold Separately 30mm twin screw barrel/screw is same design as 72mm for Development/Lab/Small Lots, cold cut, matching above process)

1.) Extruder 2 (two) 72mm Model PSM72machines Tiwn Screw Co-Rotational :

A.) Mfg. # M7203033 setup for: Cold cut stand into pelletizer

B.) Mfg. # M9203033 setup for: Hot cut with "Gala type" process

C.) Electrical each requires 400 amps of 460/3/60 to main panel

D.) Overall Extruder area/size/foot print is 3' width by 22' length by 6' height

F.) Controlled by movable Sino-Alloy, Model Sino PSR 510

2.) Motor: 150hp/110kw, 460/3/60, 250amps, variable speed 175-1750 RPM into gearbox

3.) Gear Box: Ratio 1: 5.74, Output speed 30-300 RPM's

a.) Feed Throat 1 (one) at 260mm length

b.) Barrels process - 11 (eleven) total at 260mm length each, with 2 (two) are vented and 1 (one) is side feed combo and other 8 (eight) Closed.

c.) Screen changer 4" screen also 8/0 area 1 (one) 320mm Barrel length

d.) Transition Head/Die plate - 1 (one) 150mm section length

e.) Screw Length overall 3302mm with Feed throat to screw tips 3000mm 72mm = 42 ratio

5.) Side Feeder: Sino-Alloy Model PSC70, 70mm Twin screw, Variable speed 18-168 RPM's

- Gearbox: Transcyko, Model: THM3-611, Mfg# 20420015, 3-hp input

- Motor: 3hp 6206ZZ 6305ZZ mfg# 3235280006K

6.) Screen Changer: Slide Plate type, 4" breaker Plate, Hydraulic slide by 5hp pump.

7.) Pelletizer systems different on Extruder A.) versus Extruder B.)

7A.) Cold cut Strand 17 hole strand die

a1.) Waterbath: I.D. 23" width by 15' length by 12" depth and Overall size 34" width by 15'-6" length by 42" height has strand airknife and close loop re-circulation loop with heat exchanger and pump.

a2.) Pelletizer: Cumberland, Model 14-Pelletizer, Rotor 14" solid with 24 tooth, 40 hp, Serial# 32300-682 Overall size 62" wide front infeed by 48" side by 7'-6" height.

a3.) Screener: Mfg. Sino-Alloy Rectangle surface area 29" by 68" triple screen (remove fines and over's) with air cooled by blower supplying air under screener deck. Overall size 40" width by 123" length by 29" height with 12" by 12" control box on stand with 38" height. Bottom infeed for air blower 8" dia.

7B.) Hot face die Cutter 36 hole die plate:

b1.) Hot face cutter mfg. Sino-Alloy, 6 (six) knife, 10 hp / 7.5kw, 480v/3p/60hz, Variable speed controls Mfg. Teco, Model: Speecon 7200MA.

b2.) Spin Dryer (Gala Type) Mfg. Sino-Alloy, skid mounted unit with drive 5.4hp / 4kw motor, blower, control panel and heat exchanger. Infeed 2" dia, pipe, Inner Screen dia.12" by 48" height (2 (two) screens 24" height each) and discharge 4" by 8". Overall size 7' width by 7' length by 9' height.

b3.) Screener: Mfg. Sino-Alloy Rectangle surface area 29" by 68" triple screen (remove fines and over's) with air cooled by blower supplying air under screener deck. Overall size 40" width by 123" length by 29" height with 12" by 12" control box on stand with 38" height. Bottom infeed for air blower 8" dia.

8.) Feeders into Extruder: both K-Tron Loss-in-Weight and Sino-Alloy feeders:

A.) Feeder Twin Screw 2 (two) Mfg. K-Tron, Type: K2-ML-T35/DR, Reduction: High 3.34:1 with top agitator or bridge breaker.

B.) Feeder Single Screw 2 (two) Mfg. K-Tron, Type: K2-ML-S60/DR, Reduction: High 3.6:1

C.) Sino-Alloy, Main Feeder, single screw Gravimetric with Agitator or bridge breaker above screw; was used for glass and or Talc feed.

2 (two) Vac-U-Max vacuum transfer

1 (one) Super Sac hanging station used for chopper glass.

10.) Catwalk was installed to support "both" 72mm Twin Screw Extruders together; can not be split.

11.) Other support equipment not listed and available depending on purchase price.

Additional Questions or Info ****@gmail.com or phone (***)-438-7656 USA