Wisconsin Parts Database Instructions and Discussion Team/Group > WISCONSIN

> Electrical Components

> Add

> New

> Without Warranty

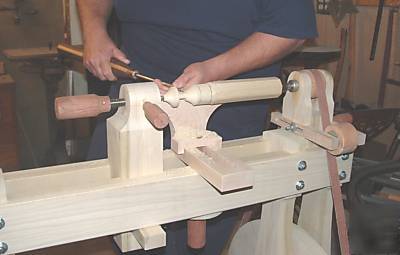

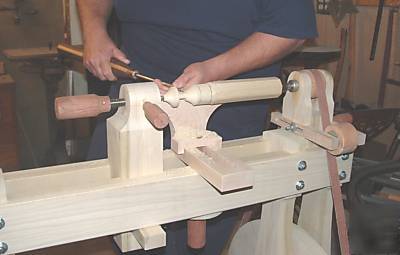

> Woodworkers treadle lathe, woodbodied and foot operated

Woodworkers treadle lathe, woodbodied and foot operated

Woodworkers Treadle Lathe, Woodbodied and Foot Operated

New Extended Bed can turn 26" between centers!

* Approximate Dimensions 42" Tall, 40" Long and 24" Wide.

* Total Weight is Approximately 95LBS.

* 26" between centers, over 5 " from center to top of bedway.

* Bedways are 40" Long made from 1 3/4" Poplar.

* Shafts are 5/8" Diameter Drill Rod running in oil impregnated bronze bearings.

* 24" Diameter, 1 3/4" thick solid Poplar Flywheel.

* Tool Rest made from Hard Maple.

* Handles are made of Bubinga.

* Easy assembly and Disassembly for moving or storage-Assembly instructions with pictures included.

* Can be available for a "Test Drive" in my Shop.

As my wife and I have been bringing our hand tools to various tool shows to sell we have also been demonstrating my large oak body Treadle Lathe as an "attention getter". I was surprized at how many questions we got about it, especially if we made them for sale. Because of that interest I decided to design a simple wood bodied Treadle Lathe to add to our tool line.

The Lathe occupies a space only 42" Tall, 40" Wide and 24" Deep. The machine is constructed primarily of 1 3/4" thick Poplar and weighs about 95LBS. The Flywheel is 24" in Diameter and made of 1 3/4" Poplar. The Flywheel Hub is a 6" Diameter casting pinned to the 5/8" Diameter Shaft with a spring pin. The Flywheel runs very true with less than 1/8" runout at its very edge-not too bad for a woodbodied machine.

The Head Stock is removable and bolts in place between the bedways. The Drive Shaft is 5/8" Diameter Drill Rod, the Drive Pulley is made of Cherry and fixed to the Drive Shaft with 2 set screws.

The Treadle Lathe is supplied with a custom made Screw Chuck. If you have never used a Screw Chuck before, I think you may be surprised at the ease of set up - you simply pre-drill a small pilot hole in the center of the work piece and screw the chuck to it. For this type of Lathe, friction is always a concern, I feel a Screw Chuck is an ideal work holding solution for Spindle turning.

I fitted the Head Stock with an adjustable Cherry wood Idler Pulley Assembly to take up any eventual wear or stretching in the belt. I have been using the prototype Lathe for a couple of months now and have not had to use the Idler Pulley as yet-the belt runs tight and true.

The Tool Rest is made of Hard Maple to slow down wear. It is a simple design with the height fixed at about 1/8" below center. That height seems to work the best on this Lathe. The Tool Rest is held in place by a wooden screw and nut which tightens everything up to the Bedways.

The Tail Stock is fixed in place with a wedge. The dead center is custom made from 5/8-8 acme threaded rod, has a Bubinga handle and can be locked in place with the Tail Stock Center Friction Locking Screw, also made with a Bubinga handle.

The CrankArm is made from Aluminum and is held to the Flywheel Shaft with a set screw. The Pitman Rod is 3/16" Diameter Drill Rod designed for a simple sliding fit into the CrankArm and Treadle.

All the Shafts, except the Idler Pulley Shaft, which does not turn, run in oil impregnated bronze bearings, which are common hardware store items if they ever need replacing.

The Belt is 1" wide, 3ply neoprene, custom fit for these Lathes (in over 15 years on my large Lathe I have never had to replace the belt).

The entire machine can be assembled and disassembled with only 2 Tools, an Adjustable Wrench and an 5/32 Hex Key (not included but available at any hardware store).

To keep the price as reasonable as possible I have only rough sanded up to 120 grit and no finish is applied. The purchaser will be responsible for final sanding and finishing in any way they see fit.

If you have any questions or would like to "Test Drive" the Treadle Lathe in my shop, please contact us ****@comcast.net. I have also posted some Questions and Answers about the Lathe In the "Frequently asked Questions" page in my store.

Action photos are of my prototype Lathe which is identical to the Lathe listed for sale. We have also included a photo of the prototype finshed to give you an idea of the possibilities.

**Thank you for purchasing products made in the USA***