Wisconsin Parts Database Instructions and Discussion Team/Group > OTHER STATES

> Industrial Parts

> Remove

> Used

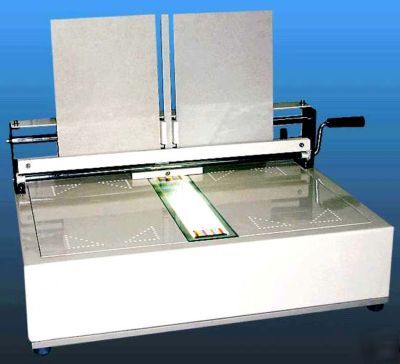

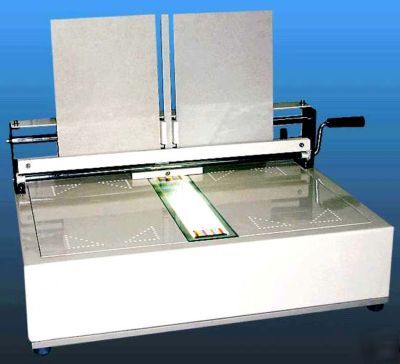

> Hardcover, hardback or hardbound machine

Hardcover, hardback or hardbound machine

anyone easily make custom hard covers

The size of operation desk 530 420mm (20.8' X 16.5')

The thickness of board 0.5~6mm

Refraction And reflection mechanism yes

The function of negative pressure absorption yes

Steps to creating a custom hard cover (case book):

Step One: Insert your chipboard or card stock in the rotating arm of the H530 and turn on the table light.

Step Two: Print your image on super-size tacking sheet (ink jet or laser material). You can optionally laminate the sheet using an 8 micron laminate for protection. Peel off the pressure sensitive backing and lay the sheet face down on the H530 table.

Step Three: Rotate the H530 arm, which lowers the card stock onto the tacking sheet in the precise position. Trim the corners at 45 degrees and fold over the four edges.

Step Four: Run the cover through the laminator to cold pressure press out any paper bubbles or wrinkles. Your hard cover is now ready for binding!

Step Five: Place a hard cover fly-sheet on each side of your book block. Bind the book on a binding machine and then peel out the backing from the fly sheets. The inside chipboard is now covered. If you wish, you can pre-print on the inside of the cover fly-sheets to give your book that extra professional touch.