Wisconsin Parts Database Instructions and Discussion Team/Group > OTHER STATES

> Industrial Parts

> Add

> Used

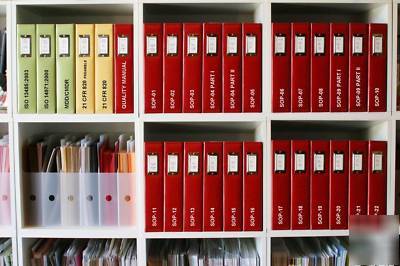

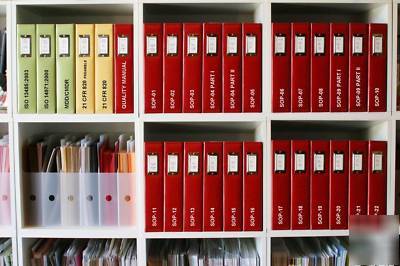

> Iso 13485 fda 21 cfr 820 qsr medical quality system

Iso 13485 fda 21 cfr 820 qsr medical quality system

ISO 13485 FDA 21 CFR 820 QSR Medical Quality System

Customizable - "Almost-Ready-to-Sign"

If you are a Class I or II Medical Device Developer or Manufacturer, you are required by law to be compliant with the FDA Quality System Regulation (21 CFR 820). We can provide a complete 21 CFR 820/ISO-13485 compliant Quality Management System (QMS) for your company for only $2,950. We will email you a complete QMS in Microsoft Word format which you can customize and deploy in about five hours. Our comprehensive QMS is fully compliant with the following regulations:

MDD 93/42/EEC (as amended by 2007/47/EC)

CMDR SOR/98-282 (Health Canada)

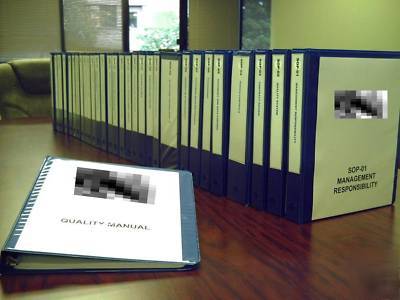

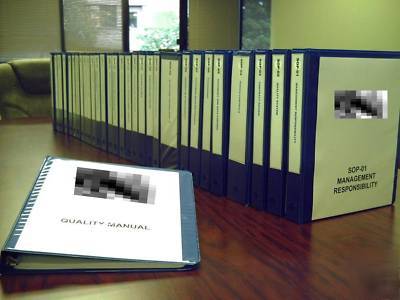

This product is a completely customizable ready-to-sign QMS consisting of 23 document folders (one for each SOP and the Quality Manual in MS Word format) developed by us to be quickly customized for your company. The QMS is divided into 22 Standard Operating Procedures (SOPs) utilizing the legacy ISO-9000/EN 46001 structure that will help you pass your FDA audit. Each SOP describes in detail the processes and procedures to be implemented by your company for compliance. The following matrix defines the regulatory requirements which will be referenced by each SOP.

820.20 Management Responsibility

820.20(b)(1) Responsibility and Authority

820.20(b)(3) Management representative

Article 14: Registration of Persons responsible

for placing devices on the market

5.5 Responsibility, Authority, and Communication

5.5.1 Responsibility and Authority

5.5.2 Management Representative

8.1 Measurement, Analysis and Improvement

Section 32 (1)(j) Quality System Certificate

Section 34: Application for a Medical Device Amendment

Section 43: Obligation to Inform

Section 43.1: Obligation to Submit Certificate

Section 45: Application of Establishment License

820.20(e) Quality System Procedures

5.4.2 Quality Management System Planning

7.1 Planning of Product realization

7.2.2 Review of requirements Related to the Product

820.30(b) Design and Development Planning

860 Medical Device Classification Procedures

Article 3: Essential Requirements

Article 11: Conformity Assessment Procedures

Article 12: Particular procedure for systems and procedure packs

Article 13: Decisions with Regards to Classification

Annex I, I: General Requirements

Annex I, II: Requirements Regarding Design and Construction

Annex II, 2: Declaration of Conformity

Annex II, 4: Examination of the Design of the Product

Annex II, 7: Application to Devices in Classes IIa and Ilb

Annex IX: Classification Criteria

7.3.1 Design and Development Planning

7.2.1 Determination of Requirements Related to the Product

7.3.2 Design and Development Inputs

7.3.3 Design and Development Outputs

7.3.4 Design and Development Review

7.3.5 Design and Development Verification

7.3.6 Design and Development Validation

7.3.7 Control of Design and Development Changes

ISO 14971:2007 Application of Risk Management to Medical Devices

Section 6-7 : Classification of Medical Devices

Section 10-20: Safety and Effectiveness

(License amendment after significant change)

Schedule 1, part 1 Classification Rules for Medical Devices

820.40(a) Document Approval and Distribution

Section 55: Distribution Records

820.50(a) Evaluation of Suppliers, Contractors, and Consultants

820.90(a) Control of Nonconforming Product

820.90(b) Nonconformity Review and Disposition

7.4.3 Verification of Purchased Product

7.5.3 Identification and Traceability

8.3 Control of Nonconforming Product

Section 9(1) and (2): Manufacturer s Obligations

Product Identification and Traceability

820.120(d) Labeling Operations

7.5.3.2.3 Status Identification

Section 21 23: Labeling Requirements

Section 52 56: Distribution Records

820.70 Production and Process controls

820.70(b) Production and Process Changes

820.70(c) Environmental Controls

820.70(e) Contamination Control

820.70 (h) Manufacturing Material

7.5.1 Control of Production and Service Provision

7.5.1.2 Control of Production and Service Provisions Special Requirements

7.5.1.2.1 Cleanliness of Product and Contamination Control

7.5.2 Validation of Processes for Production and Service Provision

7.6 Control of Monitoring and Measuring Devices

8.2.3 Monitoring and Measurement of Processes

820.80 Receiving, In-process, and Finished Device Acceptance

820.80(b) Receiving Acceptance Activities

820.80(c) In-process Acceptance Activities

7.1Planning of Product Realization

8.1 Measurement, Analysis and Improvement (General)

8.2.4 Monitoring and Measurement of Product

Section 9(1) and (2) Manufacturer s Obligations

Control of Inspection, Measuring and Test Equipment

820.72 Inspection, Measuring, Test Equipment

820.72(a) Control of Inspection, Measuring and Test Equipment

7.5.2.Validation of Processes for Production and Service Provision

Control of Nonconforming Product

Corrective and Preventive Action

820.100 Corrective and Preventive Action

Section 57(a): Maintain record of all reported device

Section 57(b): Maintain records of actions taken following reported problems and

Section 59 62: Mandatory Problem Reporting

Section 14: Characteristics and performance of medical device not affected by transport or storage

820.180 Records General Requirement

820.180(b) Record Retention Period

Annex II, 6: Administrative Provisions

8.2.3 Monitoring and Measuring of Processes

Qualification, Certification and Training Process

6.2.2 Competence, Awareness and Training

7.5.1.2.3 Servicing Activities

820.250 Statistical Techniques

Article 10: Information on incidents occurring following placing of devices on the market

In addition to the Quality Manual, and Standard Operating Procedures referenced above, the following Quality Processes (QPs) and ready-to-use Forms are provided:

* QP-01-01, Medical Device/Establishment License

* QP-01-02, Obligation to Inform

* QP-03-01, Order Processing

* QP-04-01, Design and Development Planning

* QP-04-02, Design Reviews

* QP-04-04, Device Classification for MDD

* QP-04-05, Device Classification for Health Canada

* QP-04-06, Device Classification for FDA

* QP-04-07, Risk Analysis Planning

* QP-04-08, Design Output and Verification

* QP-04-09, Design Validation and Design Transfer

* QP-04-10, Software and Electronics

* QP-04-11, Design History File

* QP-06-01, Purchasing Process

* QP-06-02, Verification of Purchased Product

* QP-19-01, Decontamination Procedures

* QP-22-01, Incident Report Process for MDD

* QP-22-02, Incident Report Process for Health Canada

* QP-22-03, Recalls for MDD

* QP-22-04, Recalls for Health Canada

* F-01-01, Management Review Report

* F-01-02, Organizational Chart

* F-04-01, Project Initiation Document

* F-04-02, Product Description

* F-04-03, Master Project Plan

* F-04-04, Design Review Report

* F-04-05, Feasibility Report

* F-04-06, Design Input Document

* F-04-07, Risk Analysis Plan

* F-04-08, Verification Plan

* F-04-09, Manufacturing and Quality Plan

* F-04-10, Regulatory Submittal for FDA

* F-04-11, Essential Requirements Checklist for MDD

* F-04-12, Declaration of Conformity for CE

* F-04-13, Declaration of Conformity for Canada

* F-04-14, Process Validation Report

* F-04-15, Validation Plan

* F-04-16, Design Transfer Plan

* F-04-17, Software Requirements Specification

* F-04-18, Software Design Specification

* F-04-19, Traceability Analysis

* F-05-02, Deviation Request

* F-05-03, Quality Agreement

* F-06-01, New Supplier Approval Evaluation

* F-06-02, Quality System Audit

* F-09-01, Preventive Maintenance Schedule

* F-09-02, Master Validation Plan and Protocol

* F-10-01, Receiving Inspection Log

* F-11-01, Inspection, Measuring, and Test Equipment Documentation

* F-13-01, Nonconforming Materials Report

* F-14-01, Corrective Action Request

* F-14-02, Preventive Action Request

* F-16-01, Device History Record

* F-16-02, Department Quality Records

* F-16-03, Software Revision Level History

* F-17-01, Internal Quality Audit Schedule

* F-17-02, Internal Audit Report

* F-17-03, External Audit Report

* F-18-01, New Employee Training Checklist

* F-18-02, Employee Training Record

* F-18-03, Training Evaluation

* F-21-01, Complaint Report

* F-21-02, Adverse Event Investigation

* F-22-01, Competent Authority Listing

* F-22-02, Minister of Health Address Health Canada

* F-22-03, Initial Incident Report for MDD

* F-22-04, Initial Incident Report for Health Canada

* F-22-05, Final Incident Report for MDD

* F-22-06, Final Incident Report for Health Canada

We can also assist your company in the implementation of your ISO-13485 QMS and provide additional services including 510(k) (Class I & II) and CE Master/Technical File preparation & submission. We have a certified Regulatory Affairs consultant and senior documentation specialists available to assist you with any regulatory matters. Email us to discuss your specific requirements!

* Code of Federal Regulations, Title 21 (21 CFR) Part 820 Quality System Regulation; Part 803 Medical Device Reporting; Part 806 Medical Device Corrections and Removals; Part 821 Medical Device Tracking.

** The "international" standard EN ISO 13485/AC is dated June 2007.