Wisconsin Parts Database Instructions and Discussion Team/Group > OTHER STATES

> Electrical Components

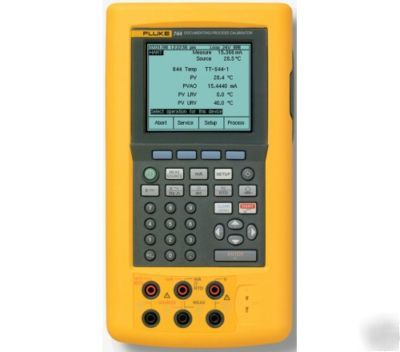

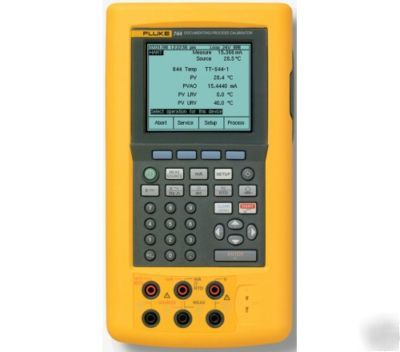

> New fluke 744 doc. process calibrator * * msrp 5,995 usd

New fluke 744 doc. process calibrator * * msrp 5,995 usd

Fluke 744: Two sets of TL24 industrial test leads, two sets of AC20 test clips, one set of TP20 test probes, a BP7235 battery pack, a BC7217 battery charger, an instruction manual, NIST-traceable calibration report and data, and three year warranty. Every 744 includes a serial port cable, HART communications cable and a DPC/TRACK Sample, which includes utilities to upload calibration data to a PC and export to PC data files.

The 744 offers all of the capabilities of the powerful Fluke 743B, plus the ability to maintain and calibrate selected HART transmitters without a second tool.

As more and more process plants begin to take advantage of smart transmitters, the need for a new generation of calibrators has emerged-calibrators that can communicate via industry standard digital protocols.

The 744 combines HART communication capability with the popular 740 Series Documenting Process Calibrators to deliver an integrated communicating calibrator.

This rugged, reliable tool is ideal for calibrating, maintaining, and troubleshooting HART instrumentation.

* Integrated HART communication functions, permitting you to monitor, control, and calibrate HART instrumentation.

* NiMH battery with 3500 mA hour life and gas gauge.

The first field calibrator for HART instruments that's both powerful and easy to use.

The 744 offers the most complete HART implementation of any process calibrator. The 744:

* Requires no external box or second tool for everyday HART calibration and maintenance.

* Offers fast HART communication.

* Supports popular models of HART transmitters, with more devise-specific command support than any other HART field calibrator.

* Fully complies with the Data Link Layer of the HART protocol, including multiple masters, burst mode, and multi-drop configurations.

* Is easy to update as additional instruments are added and new HART versions are released.

* Is based on the 743B, the most rugged, reliable multifunction field calibrator available.

* Is backed by the service and support of the Fluke organization, a member of the Hart Communications Foundation.

The 744 is designed to take on nearly all the day-to-day tasks you now perform with a separate communicator. In fact, it offers the communication capabilities of the 275 HART communicator except for the DD interpreter, which can read command set libraries from any HART supplier. This is not necessary for daily HART maintenance.

* Generate precision electrical, temperature, or pressure signals for analog stimulus or sensor simulation.

* Simultaneously measure electrical, temprature, or pressure signals from transmitter output.

* Determine type, manufacturer, model, tag ID by interrogating HART devices.

* Read HART PV function and smart transmitter digital output while measuring analog mA output.

* Read and write HART configuration functions to make field adjustments to PV range points, damping, and other top-level configuration settings.

* Re-label smart transmitters by reading and writing HART tag and message fields.

* Clone additional transmitters by reading and storing basic HART configurations.

* Perform automated HART sensor trim and output trim for selected devices in conjunction with As Found/As Left tests.

* Perform loop test with simultaneous analog and digital mA readout.

* Address new, fast, pulsed-excitation smart transmitters and PLCs.

Whether you are calibrating instruments, troubleshooting a problem ,or running planned maintenance, the multifunction Fluke 743 Documenting Process Calibrators help get the job done faster. It does so many different tasks, so quickly and so well, it's the only process calibrator you need to carry.

* Versatile HART Protocol support

* HART Transmitter Calibration Application Note

* HART Operating Modes Supported

* Differential pressure flow instrument calibration

Versatile HART Protocol support

The 744 supports the commands contained in HART protocol Version 5.7. With 2 MB of memory, the 744 supports a substantial set of HART instructions:

* Universal commands provide functions that are implemented in all field devices, for example, read manufacturer and device type, read primary variable (PV), or read current output and percent of span.

* Common practice commands provide functions that are common to many but not all field devices, for example read multiple variables, set damping time, or perform loop test.

* Device-specific commands provide functions that are unique to a particular field device, for example sensor trim.

HART Transmitter Calibration Application Note

Revised November, 2000, this document covers the subjects on this page in greater detail. Because it has 16 pages, it may take time to open. Read the Application Note. (PDF, 1.05MB)

HART Operating Modes Supported

* Point to Point operation , the most commonly used mode, connects the 744 to a single HART device in a 4-20 mA loop.

* In Multi-Drop mode , several HART instruments can be bussed together. The 744 searches for each, identifies addresses in use, and allows you to select the instrument for calibration and related operations.

* In Burst Mode, the HART instrument transmits bursts of data without waiting to be interrogated by a master unit. The 744 can take transmitters out of burst mode during test or calibration, then later restore them to burst mode.

The Fluke 744 Version 2.1 software upgrade includes:

* Device-specific calibration support for newer revisions of presently supported instruments: Honeywell ST3000 Rev 2, Rosemount 1151 Rev 6, Rosemount 3144 Rev 2, Rosemount 644 Rev 4 and Rev 5, Yokogawa EJA Rev 2, Yokogawa YTA Rev 2, Endress & Hauser Cerabar S Rev 5, and Endress & Hauser Deltabar S Rev 5.

* Device-specific calibration support for additional instruments: ABB/Hartmann & Braun Contrans P (AS 800 series) Rev 2, Endress & Hauser Cerabar M Rev 1, Foxboro IAP/IDP/IGP Rev 1, Foxboro RTT20/Eckardt TI20 Rev 1, SMAR LD301 Rev 3, and Yokogawa YTA 110 and 310 Rev 1.

* New HART capability for supported transmitters: Change HART Temperature Sensor Configuration (e.g. TC to RTD) and Change HART Temperature Sensor Wire Configuration (e.g. 2-wire to 4-wire)

* New measure/source units: Temperature in Kelvin, Temperature in degrees Rankine, and Pressure in Water Column @ 20C

* New features: Selectable Unit in Square Root Test Error Summary and User-enterable Calibration Adjustment Points

The upgrade is delivered on a floppy disk. One upgrade disk is required for each calibrator to be upgraded. Download from your PC to your calibrator using the serial cable originally supplied with your Fluke 744 Calibrator. Elapsed time for the process will be about 8 minutes. After the upgrade is complete, your calibrator will indicate Version 2.1 at start up.

The 2.1 upgrade is available from your regular Fluke dealer or representative as Fluke 744V20. For an available five-pack, ask for Fluke-744V2V.

Additional information about the software upgrade.

DPC/TRACK software for instrumentation management

Manage your instruments and your calibration data with this easy-to-use instrumentation management database.

* Create calibration procedures, lists, and instructions on your PC and download them to the 744.

* Upload your calibration data back to your PC.

* Print reports or export data in standard ASCII format.

* Additional information about the Fluke DPC/TRACK.

Other Software Packages for Instrumentation Management

The scheduling of calibrations, creation of procedures and documentation of your calibration results can also be facilitated by a number of other instrumentation management software packages:

* Beamex QM6 Quality Manager Calibration Software

* Cornerstone Cal Station and Base Station

* Honeywell Loveland DocuMint

* Fisher Rosemount Asset Management Solutions

* Blue Mountain Quality Resources

DPC/TRACK is a trademark of Fluke Corporation.

QM6 is a trademark of Beamex, Inc.

Cornerstone is a trademark of Applied System Technologies.

InstruMint and DocuMint are trademarks of Honeywell.

Covers virtually any pressure application including gage, differential, dual (compound), absolute, and vacuum.

* Includes NIST-traceable calibration certificate.

A family of twenty-nine optional pressure modules provides pressure calibration and measurement capabilities. Twenty-nine modules are available, with basic accuracy specsto 0.05%. Ranges start at 0-10"H20 (0-2.5kPa) and go to 0-10,000 psi (0-70,000 kPa).

Allow you to quickly set up powerful, automated calibration procedures for linear transmitters, DP flow transmitters, and one- and two-point limit switches. Simply select the appropriate measure and/or source functions and fill out the procedure template. The 740 Series does the rest. It quickly performs the test, calculates the errors, and displays the final results, highlighting out of tolerance points.

Enable you to map one unit to another, such as mV to C or F. Allows you to use the Fluke 740 Series with millivolt output accessories such as the Fluke 80T-IR Temperature Probe, and to document tests using non-supported units such as parts per million or revolutions per minute.

Enables technicians to record calibration results that were sourced and/or measured by other devices such as panel meters or readout-only devices.

Procedures perform fast, automated calibration of one and two-point limit switches for voltage, current, temperature, and pressure.

Differential pressure flow instrument calibration

Routines use a square root function to directly calibrate DP flow instruments.

Calibrate temperature, pressure, voltage, current, resistance, and frequency. Since it both measures and sources, you can troubleshoot and calibrate all with one rugged tool.

The easy-to-follow menu-driven display guides you through any task. Get up to speed in minutes, not days. Programmable calibration routines enable you to create and run automated as-found/as-left procedures to ensure fast, consistent, calibrations.

Records and documents results

To support your ISO-9000 or regulatory standards the Fluke 741 captures your calibration results, eliminating the need to juggle a pen and pad in the field.

Small enough to fit easily into a tool bag and to use in tight spaces. Runs an entire shift on a rechargeable NiCd battery pack.

Lets you read your results in any kind of light.

Provide one-touch access to enhanced functions such as task lists, automated procedures, scaling, min/max, stepping and ramping, and review memory.

Measure, Source, or simultaneous Measure/Source, - enable technicians to troubleshoot, calibrate, or maintain instrumentation with just one tool.

Displays instructions in English, French, German, Spanish, and Italian.

Built-in algebraic calculator

With four functions-plus square root-stores, recalls, and performs calculations required for setting up instruments or evaluating data in the field. Use it to set the source function to a calculated value. There's no need to carry a pencil and paper or a separate calculator.

Programmable measurement delay

Inside automated procedures permits calibrating instruments that respond slowly.

(% of reading+% of full scale)

Temperature, RTDs, and Thermocouples*

* Resolution: 0.1 C, except 1 C for 10W Cu. Best case, mid-range accuracies. Sensor inaccuracies not included. For 2-wire and 3-wire RTD measurements, add 0.4 C. Thermocouple accuracies with external cold junction. For internal junction add 0.2 C.

Operating Temperature: -10 C to 50 C (-20 C typical except for frequency and ac voltage measurement)

Storage Temperature: -20 C to 60 C

Operating Altitude: 2800m above mean sea level (9186 ft)

Enclosure Protection: Designed to meet IEC529 IP52 (normal operating vacuum for dust)

Measure functions: Voltage, current, resistance, frequency, temperature, pressure

Reading rate: 1, 2, 5, 10, 20, 30, or 60 readings per minute

Maximum record length: 8000 readings (7980 for 30 or 60 readings per minute)

Source functions: Voltage, current, resistance, frequency, temperature

Trip Detect: Continuity or voltage (continuity detection not available when sourcing current)

Voltage: Selectable, 24V or 28V

Maximum current: 22 mA, short circuit protected

* (all calibrator specifications apply from +18 C to +28 C unless stated otherwise)

Via snap-shut door without opening calibrator; no tools required

* RS-232 connector to interface to your PC

* Connection for optional battery eliminator

Complies with CAN/CSA C22.2 No 1010.1-92, ASNI/ISA S82.01-1994, UL3111, and EN610-1:1993

The standard specification intervals for the 744 is 1 and 2 years. Typical 90 day measurement and source accuracy can be estimated by dividing the one year "% of reading" or "%of output" specifications by 2. Floor specifications, expressed as "% of f.s." or "counts" or "ohms" remain constant.

744 User's Manual (PDF, 1.96MB)

744 User's Manual Supplement (PDF, 8kB)

744 HART Mode User's Guide (PDF, 584kB)

744 HART Mode User's Guide Supplement (PDF, 6kB)

744 V2.0 Upgrade Instruction Sheet (PDF, 10kB)

74X Calibration Manual (PDF, 429kB)

DPC/TRACK User's Manual (PDF, 825kB)

DPC/TRACK Installation Guide (PDF, 15kB)