Wisconsin Parts Database Instructions and Discussion Team/Group > INDIANA

> Machine Parts

> Remove

> Used

> High frequency (hf) induction welder - owner's manual

High frequency (hf) induction welder - owner's manual

High Frequency (HF) Induction Welding Machine - High Frequency (HF) Induction Heating System

Fully operational. Price is F.O.B. Montevideo, Uruguay.

Full Manual available. Extract from Manual below.

1. NAME OF SYSTEMPLASTIC WELDING

2. THEORY OF APPLICATIONAFTER HEATING OF METAL GRILLE BY INDUCTION HEATING MACHINE SOME SPECIAL DESIGNED PRESS WOULD PRESS THIS HEATING METAL GRILLE INTO PLASTIC AND THE PLASTIC WILL BE MELT BY THE HEATED GRILLE AND BE WELDED TO EACH OTHER3. COMPOSITION OF EQUIPMENT

2. MAlN SPECIFICATION OF GENERATOR

1. INPUT POWER SOURCE - 3 PHASE 220V 30KVA I

4. CAPACITY OF MAlN -TRANSFORMER - 30 KVA

7. TYPE OF OSCILLATING - PLATE-TURNED, SELF OSCILLATION

8. RECTIFIER - - - THREE PHASE, FULL WAVE RECTIFICATION

9. POWER CONTROL - THYRISTOR PHASE CONTROL

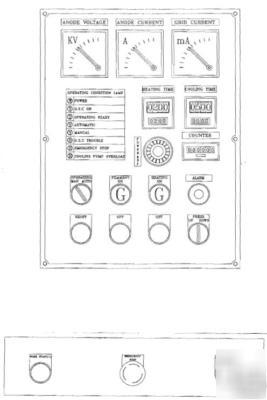

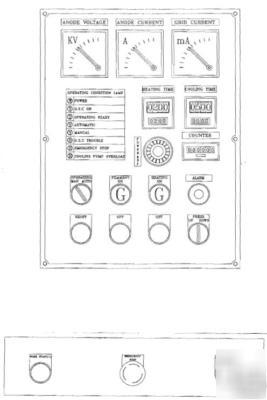

1. VOLTAGE METER: DISPLAY THE INPUT POWER SOURCE

2. AMPER METER : DISPLAY THE VOLUME OF CURRENT FLOW

3. CAM S/W (V) : DISPLAY VOLTAGE OF EACH PHASE BY VOLTAGE METER S/W.

4. CAM S/W (A) : IIISPLAY THE CURRENT VOLUME BY AMPERE METER S/W.

"ON" WHEN OVERLOAD OF FILAMENT TUBE AND CLEARED BY RESET S,W

"ON" WHEN LACK OF COOLING WATER'S PRESSURE AND CHECK THE COOLING WATER PRESSURE S/W PSI, AND IT'S LINE IF FLOW IN REGULAR OR NOT.

"ON" WHEN NOT FLOW NORMAL, CHECK IT'S LINE OF COOLING WATER AND VALVE. FS1.

"ON" WHEN OPENED DOOR OF OSCILLATOR, AND CHECK OF IT'S DS2

f. O.C.R. (OVER CURRENT RELAY)

"ON" WHEN OVER CURRENT FLOW IN OSCILLATOR AND RESET THE O.S.C. S/W TO CLEAR IT.

g. COOLING WATER & PANEL OVER TEMP

"ON" WHEN THE TEMPERATURE OF INNER PANEL OR COOLING WATER IS HIGH THAN SETTING TEMP. THE TEMPERATURE OF INNER PANEL AND COOLING WATER SHOULD BE LOWER THAN SETTING TEMPERATURE. THE TEMPERATURE SHOULD BE SET ON MAX 45 C

"ON" WHEN OVER CURRENT FLOWS TO PCB OF SCR CONTROL PUSH THE RESET S/W IN PCB UNIT.

WHEN WANT TO OPERATE THE COOLING PUMP BY MANUAL, PUSH IT AND THEN PUMP OPERATE.

WHEN NEED STOP THE COOLING WATER PUMP PUSH IT AND THEN STOP THE PUMP AFTER AROUND 1 MINUTES

* AFTER STOP OF PUMP, SHOULD BE OFF THE MAIN SOURCE AFTER WORK